Uses

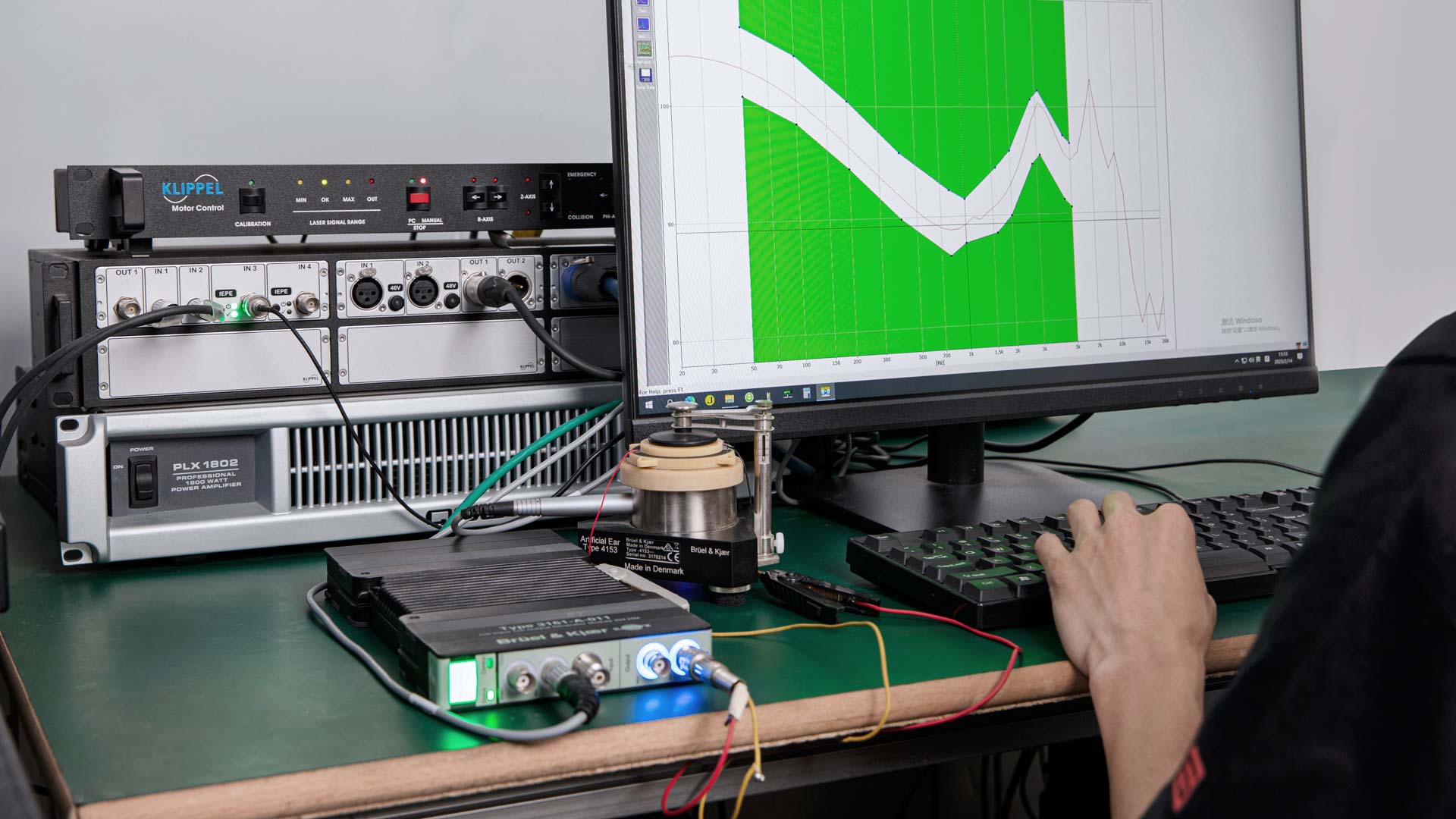

Pre-qualification of electro-acoustic transducers

Sample testing and quality assurance of electro acoustic transducers

Linear and non-linear system analysis

Main features

Precision acoustic measurement such as SPL (Sound Pressure Level), harmonic distortions, and impedance both in magnitude and phase domains

Loudness rating calculation

Uses

Precision electrical audio signal measurement such as level, THD+N (Total Harmonic Distorsion + Noise), S/N (Signal to Noise ratio), wawe form, etc., down to -120dB noise level

Main measurement

Level

Frequency response

TDH+N

Phase

Crosstalk

Noise level

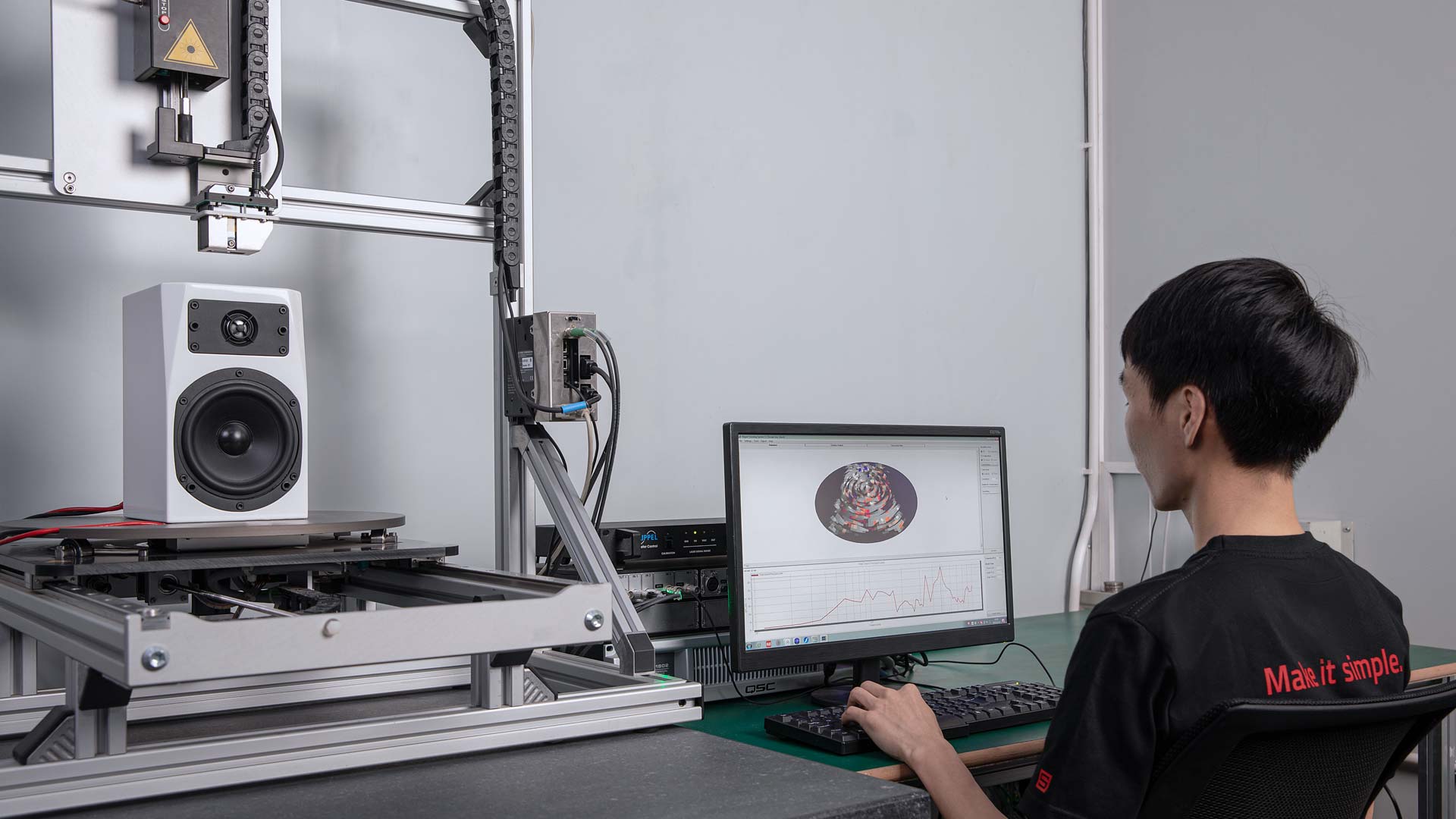

Uses

Measure the vibration and geometry of radiators,

enclosures and mechanical structures used in loudspeaker,

micro-speaker and other electro-acoustical

or electro-mechanical transducers.

Measure transducers mounted in an enclosure or in free air

Main features

Measure geometry and mechanical vibration of the transducer

Visualize the vibration behavior

Identify the Large Parameters and Thiel-Small parameters of any dynamic acoustic transducers

Uses

Simulation software for designing driver and loudspeaker

Main features

Vibration of diaphragm / cabinet

Magnetic field of motor

Sound wave dispersion in free air

User-defined material

Uses

Allow to conduct acoustic measurement and experiment in nominal "free-field" conditions without reflected sound wave

Main features

Background noise levels in the less than 15 dBA

Chamber internal size: 4400L*2600W*2600H

Uses

Performs accurate and precise physical and geometrical measurements on loudspeaker cabinets and components. It helps engineering and quality personnel to determine and make sure they conform to product and quality specifications from prototype to production stages.

Efficiently support various engineering and quality assurance tasks including FAI, CPK, sample examination & quality specification definition and regular production QC inspection

Main features

CMM model: Carl Zeiss Spectrum with Zeiss Calypso metrology software

Programmable measuring job improves measuring efficiency

Measuring range: 1000*1600*600 (X/Y/Z axis)

Accuracy: 5.6 μm

Length measurement error (E0): 2.4 μm+L/300

Single stylus form error (PFTU): 2.7 μm

Uses

In-house quick and precise validation prototyping including concept modeling, form and fit testing, functional prototyping

Main features

3D printer model: 3D Systems ProJet MJP 2500

MultiJet (MJP) 3D printing technology

High Definition Resolution of 800 x 900 x 790 DPI

Using UV-curable liquid resin and wax-based supports

Uses

Simulate variety of conditions to analyze and identify the strengths and limitations in designs and set specification (hence warranties) of product.

Condition samples prior to testing.

Main features

Programmable temperatures & humidity control

Chamber volume: 1500L & 1000L

Temperature range: -40°C to +150°C

Humidity range: 20%RH to 98%RH

Accuracy: ±1°C and ±2%RH

Ramp Rate: 3°C per minute (heating) and 1°C per minute (cooling)